Introduction

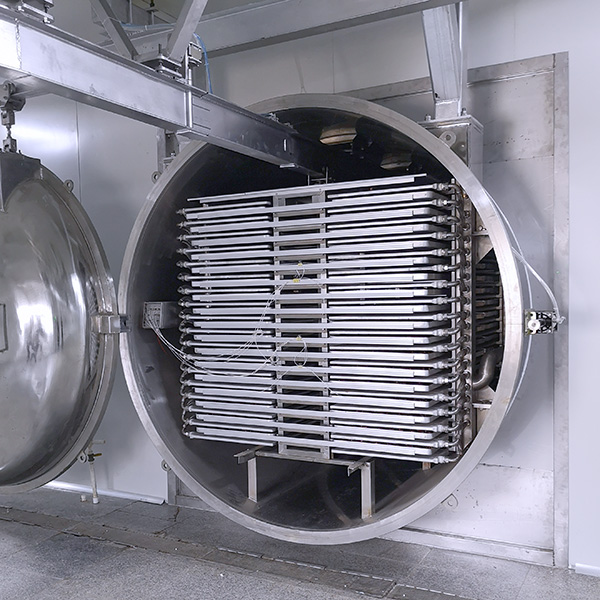

The FD-200R industrial freeze dryer machine offers 206m2 shelf area and up to 3300kgs vapors collect capacity. It capable of drying fruits, vegetables, cooked meals and pet food.

Technical Spec.

| Model | FD-200R |

|---|---|

| Shelf Area | 206m2 |

| Shelf Modules | 4 |

| No. of Shelves | 17+1 |

| Shelf Size | 630*5300mm |

| Shelf Temp. | RT~+100C |

| Condenser Perf. | 2000Kgs/24Hrs |

| Condenser Temp. | -45C |

| Final Vacuum | <15Pa |

| Power Install | 400Kw |

| Install Area | 12*25m |

Technical Description

- Modularly freeze drying plant, easy to assemble, transport, install and maintain.

- Overhead monorail system for material quick loading unloading.

- Stainless steel, cylindrical drying chamber with insulation layer.

- Slide door with large sight glass.

- Heat transfer fluid based shelves which are always temperature controlled.

- Pure water as heat transfer medium, hygiene and safe.

- Radiation heating method, anodized aluminum alloy shelves and trays.

- External, coils type ice condenser, large vapors collect capacity.

- Vacuum system compose of backing pumps and roots pumps, quick pull chamber pressure down to set.

- Chamber vacuum auto regulate to set point.

- Water cooled, screw compressor system.

- PLC and user friendly touch screen HMI based control system.

- Industrial FD-MEGA control interface.

- Alive display system working status and key parameters.

- Recipes management.

- Real time freeze drying trend.

- Data logging and can be exported via USB.

- Automatic and semi-automatic working.

- System setting and sensors calibration.

- System log-out and password enter.

- System protections.

- Pneumatic valves for air and water isolate.

- PT100 temperature sensors for products, shelves, fluid and condenser.

- Pirani vacuum gauge for chamber pressure measurement.

- Validation documents and technical support.

- Thoroughly quality and performance test before shipment.