The Right Machine Selection Guarantees Success Business

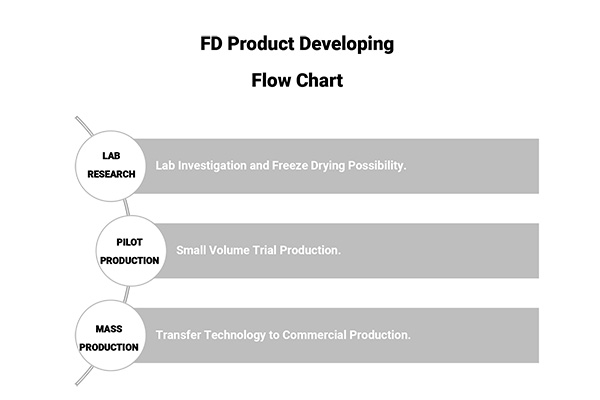

Freeze drying project is a systematic project. While an idea generated, it will go through lab investigation, small trial production, and finally commercial mass production.

This flow chart, guarantees you always in the right direction of freeze drying technology investment. When we invest a new technology, we should play it safe, is it?

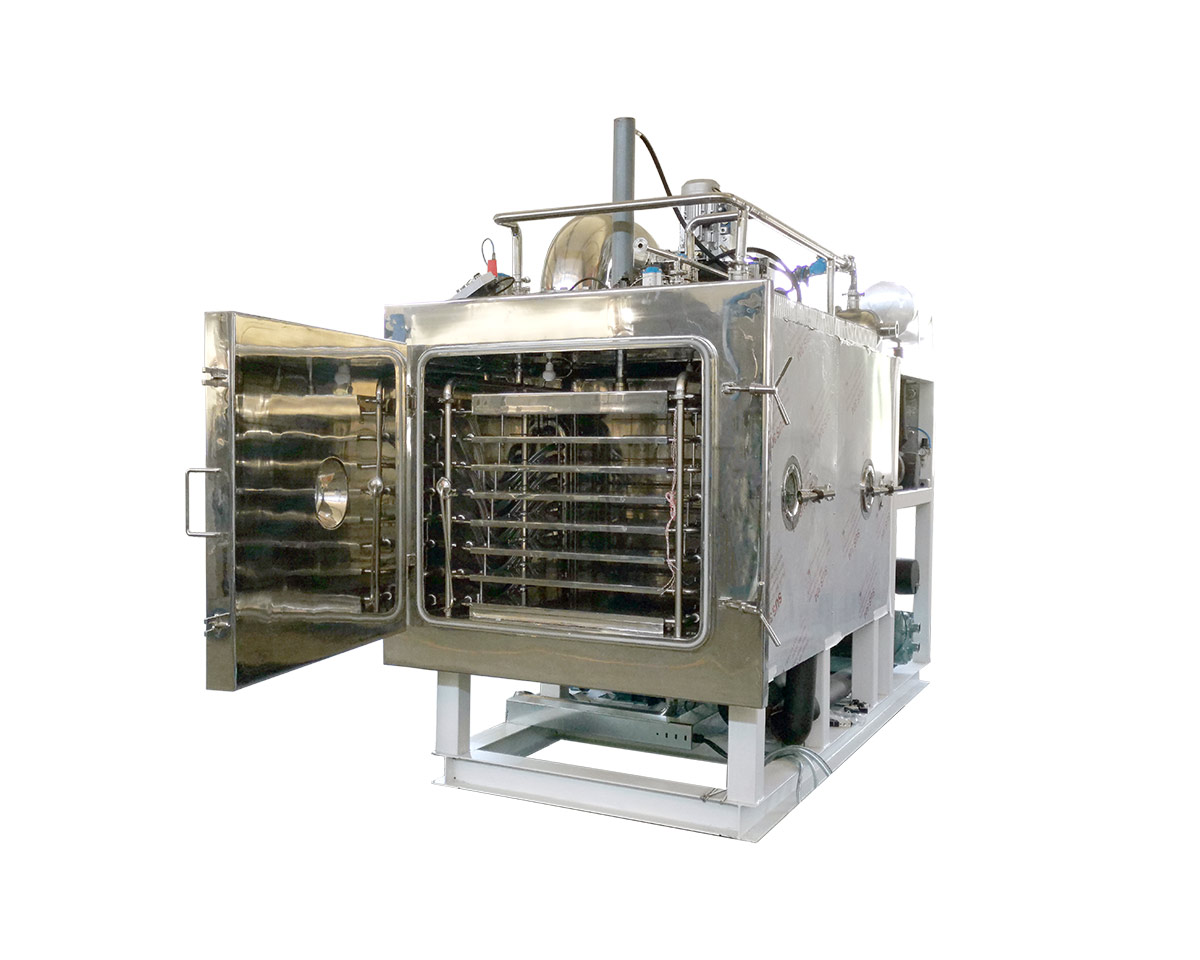

Commercial Production

Commercial and industrial mass production is the final goal of freeze drying business. Vekuma engineered and manufactured several series freeze drying equipment for industrial large production. Apply to pharmaceutical, food, nutriceutical, chemical and bio-pharma sector. Capacity up to 500kgs per load.