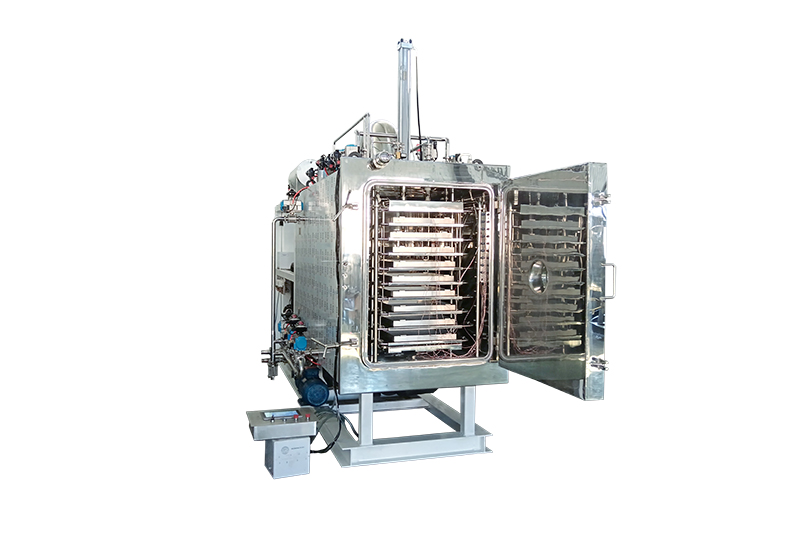

Vekuma’s FDLS freeze dryers are designed for industrial large production of a range of bio and pharmaceutical products. Typical applications include medical vaccines, antibiotics, serum, penicillin, hormones and reagents.

The FDLS freeze drying units are complete with a hydraulic stoppering system and flexible shelves for vials closing under vacuum environment. And these lyophilizers can be equipped with CIP and SIP system to satisfy commercial aseptic production needs.

Technical Specifications

| Model | FD-1LS | FD-2LS | FD-3LS | FD-5LS |

|---|---|---|---|---|

| Shelf Area | 1.08m2 | 2.16m2 | 3.24m2 | 5.25m2 |

| Shelves No. | 4+1 | 6+1 | 6+1 | 7+1 |

| Shelves Size | 600*450mm | 600*600mm | 600*900mm | 750*1000mm |

| Shelves Temp. | -55C~+70C | -55C~+70C | -55C~+70C | -55C~+70C |

| Condenser | 10Kgs/24Hrs | 20Kgs/24Hrs | 30Kgs/24Hrs | 50Kgs/24Hrs |

| Condenser Temp. | -85C | -85C | -85C | -85C |

| Final Vacuum | <1Pa | <1Pa | <1Pa | <1Pa |

| Power Install | 13.5Kw | 18Kw | 21Kw | 28Kw |

| Size W*L*H | 1200*2200*2300 | 1500*2350*2500 | 1500*2800*2500 | 1600*4000*2800 |

| 2R/4R | 4144 | 8214 | 12432 | 19964 |

| 6R/8R | 2160 | 4374 | 6480 | 10710 |

| Model | FD-10LS | FD-20LS | FD-30LS | FD-40LS |

|---|---|---|---|---|

| Shelf Area | 9.72m2 | 19.8m2 | 29.7m2 | 40.5m2 |

| Shelves No. | 9+1 | 11+1 | 11+1 | 15+1 |

| Shelves Size | 900*1200mm | 1200*1500mm | 1500*1800mm | 1500*1800mm |

| Shelves Temp. | -55C~+70C | -55C~+70C | -55C~+70C | -55C~+70C |

| Condenser | 100Kgs/24Hrs | 200Kgs/24Hrs | 300Kgs/24Hrs | 400Kgs/24Hrs |

| Condenser Temp. | -85C | -85C | -85C | -85C |

| Final Vacuum | <1Pa | <1Pa | <1Pa | <1Pa |

| Power Install | 60Kw | 85Kw | 98Kw | 125Kw |

| Size W*L*H | 1900*6000*3200 | 2200*7500*3600 | 2500*9000*3800 | 2500*9000*4000mm |

| 2R/4R | 37800 | 76725 | 114576 | 156240 |

| 6R/8R | 19440 | 40392 | 60588 | 82620 |

Technical Features

Vekuma has been designed and manufactured production scale lyophilizers for the pharmaceutical and biotechnology industry. Which is carried out in accordance with the guidelines of GMP, FDA and CE. We support your drugs development from very beginning lab research development, to process optimization, pilot production and final success in commercial and industrial mass production.

Our FDLS series pharmaceutical freeze dryers are designed for commercial and industrial large production. All models are modular engineered with standardized sub-systems that can be flexible configured as per user’s reqirement, such as CIP, SIP, redundant compressors, vacuum pumps and fluid pumps. Fit both aseptic and non-aseptic production.

Standard Features:

- 2 chambers system, ice condenser installs behind drying chamber.

- Butterfly valve for chamber and condenser isolate.

- Silicone oil based shelf module, sandwich structure for fluid circulates inside for plates heating and chilling.

- Hydraulic stoppering for vials closing, direction top to bottom.

- Electric heating of heat transfer fluids, PID control.

- 2-stage reciprocating compressor system, water cooling method.

- 2-stage oil sealed vacuum pumps and Pirani vacuum sensor.

- FDA 21CFR PART11 compliant control system, PLC and HMI based.

- Pneumatic operated valves for all air and water isolate.

- CIP clean in place.

- IQ, OPQ and validation documentation.

Tailor-Made and Options

Vekuma pharmaceutical lyophilizer can be built fully meet your production needs. Industry heavy-duty, superior craftsmanship, high-performance, flexible custom and offer possibilities of upgrade in future.

- CIP clean in place.

- SIP sterilize in place.

- Auto door lock (pneumatically).

- Door position sensor.

- Slot door.

- Variable shelf spacing.

- Butterfly or mushroom valve for chamber&condenser isolate.

- Venting filter.

- HEPA filter.

- Vacuum pump oil mist filter.

- Proportional air valve.

- Capacitive vacuum gauge.

- Redundant compressor, vacuum pump, fluid pump.

- Eutectic point detector.

- PC control.

- SCADA package.

- FAT and report file.

- System Validation documentation IQ, OQ.

- SAT and IQ, OQ execution.

- Install, commissioning and worker training.