Freeze Drying Basic

Vacuum freeze drying (also known as lyophilization) is one of the best recognized dehydration methods, and also is the only method to deliver stable, biologically active products with a long shelf life.

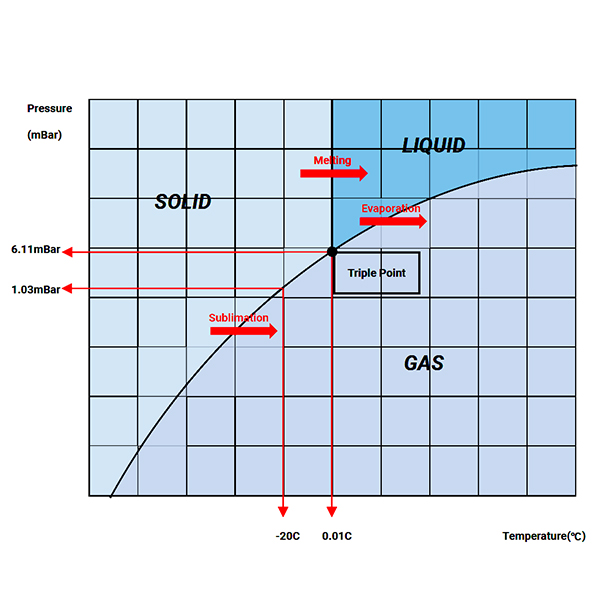

As seen from the water triple phase diagram, once pressure and temperature both lower than water triple point (6.11mbar, 0.01C), the phases transfer of water is between solid and gas, without liquid phase involved.

For freeze drying, the water phases change from solid to gas, which called sublimation. So, freeze drying starts with raw product freezing, and then reduce surrounding pressure to allow the solid ice to sublime, by this, the water in raw products is removed.

Benefits

No doubt, freeze drying has uncomparable advantages among all drying methods. Not only because it gently dry materials without ruin their physical structure and chemical properties, but also the dried products no need critical storage environment.

Here are key benefits: