Introduction

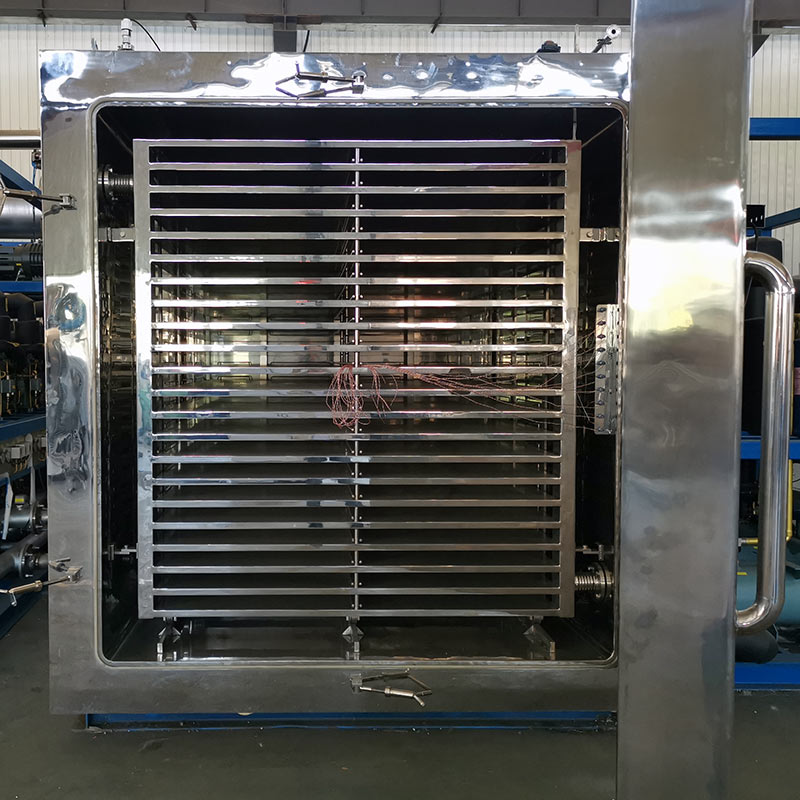

The Vekuma FD-50L general purpose freeze dryer suit industrial large production. It has 48.6m2 shelf area that enable load raw material.

The machine is split design, drying chamber and system 2 part for easy transport.

Technical Spec.

| Model | FD-50L |

|---|---|

| Shelf Area | 48.6m2 |

| Useable Shelves | 18 |

| Shelves Size | 1500*1800mm |

| Shelves Temp. | -50C~+70C |

| Condenser | 500Kgs/24Hrs, 800Kgs Max |

| Condenser Temp. | -75C |

| Final Vacuum | <5Pa |

| Power Install | 135Kw |

| Size | W/2300*L/9500*H/3850mm |

Technical Description

- Integrated or split structure.

- Advanced PLC and user-friendly HMI based control system, FD-MEGA software.

- Entirely S/S304 fabricated include chamber, shelves, trays and condenser.

- Rectangular drying chamber, high space use rate and high temperature uniformity.

- Heavy duty hinged door with large sight glass.

- Cooling and heating shelves temperature from -50C to +70C.

- External type ice condenser, lowest -75C.

- Condenser hot water defrost.

- Vacuum system adopt 2 stage oil sealed pumps + roots pump.

- System final vacuum <0.05mbar, vacuum adjustable.

- Pirani type vacuum sensor.

- Water cooled, semi-hermetic compressor system.

- Documents and validation package include in standard offer.

Design Features

PLC and user-friendly HMI based control system, LYO-MEGA V2.0 interface, has all the functions of a commercial freeze dryer is needed, to perform interlock checks, execute freeze drying processes, protect freeze dry system and your valuable material all the time. Which includes the following functions.

- Graphic display main components working status and key parameters.

- System and key parts functional test.

- Automatic and semi-automatic work mode.

- Freeze drying recipes management.

- Real-time freeze drying curve.

- Historical curve review.

- Drying data-logging and can be exported via USB.

- Users, password and authorizations.

- Sensors calibration.

- Alarms.

- Shelf cooling: +20C ~ -40C <60min

- Cooling final: -50C

- Shelf heating: -40C ~ +20C <60min

- Heating final: +70C

- Shelf temperature uniformity: <+/-1C

- Condenser cooling: RT ~ -40C <30min

- Condenser final: -75C

- Defrosting: <60Min (+65C Water)

- Vacuumize to 100Pa: <30Min

- Vacuum final: <1Pa

- Leak rate <5Pa L/Sec

- Chamber inner wall roughness Ra<0.6um.

- Shelves flatness <0.5mm/m.

- Shelves roughness Ra<0.4um.

- Condenser inner wall roughness Ra<0.6um.

- Condenser coils roughness Ra<0.4um.

- Sloped condenser bottom for water easy draining.

- All pipelines use flanges and clamps connection.

- S/S316L material.

- Door position sensor.

- Slide door.

- Coated trays.

- Venting filter.

- HEPA filter.

- Vacuum pump oil mist filter.

- Scroll vacuum pump.

- Capacitive vacuum sensor.

- Chamber and condenser isolation valve.

- Redundant compressor, vacuum pump, fluid pump.

- Eutectic point detector.

- PC control.