Introduction

Freeze drying now is the standard process in pharmaceutical industry. On market, freeze dried drugs takes one third ratio, and is raising year by year. With freeze drying, unstable and difficult to preserve pharmaceuticals turn to stable, light weight, easy storage dried products. Extend its shelf life and guarantee the biological activities.

Thus, freeze drying technology has always been considered for pharmaceutical and biological production. For some heat-sensitive material, it is the only possible choice, high add value of products.

Freeze drying is a low temperature dehydration method. During the process, at most time, products are kept in minus temperature, dried gently without damage to their physical structure or biological activities. When need, freeze dried products can be quickly reconstituted by simply add water.

Lyophilized pharmaceuticals are easy to store and transport, don’t need to be refrigerated or preserve with chemicals. No critical storage environment request, just at room temperature.

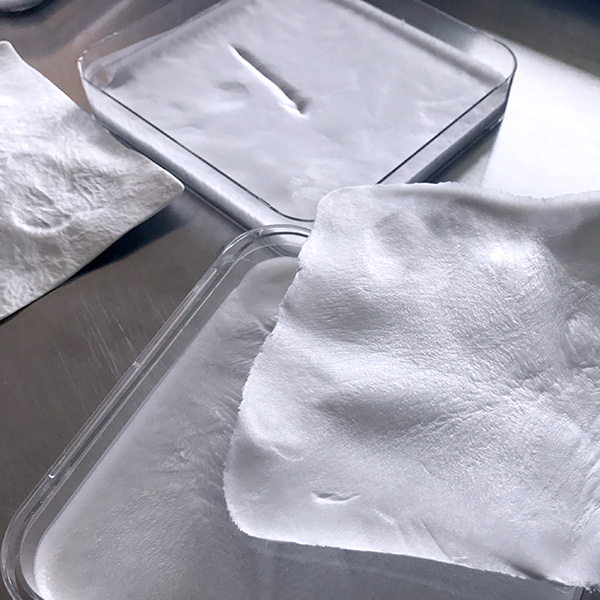

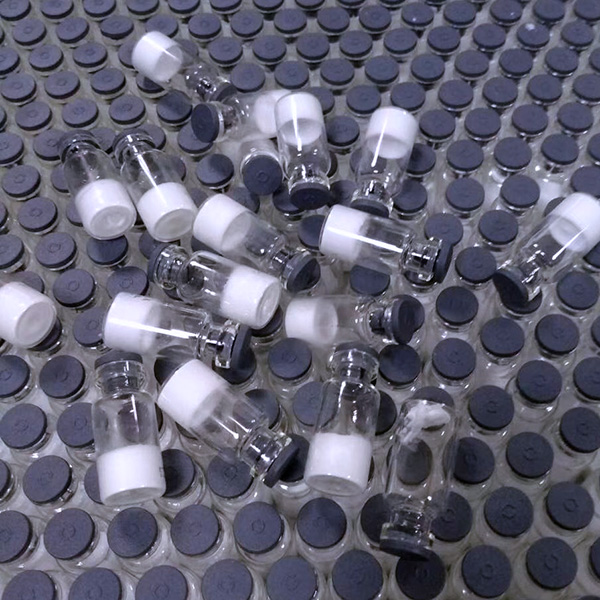

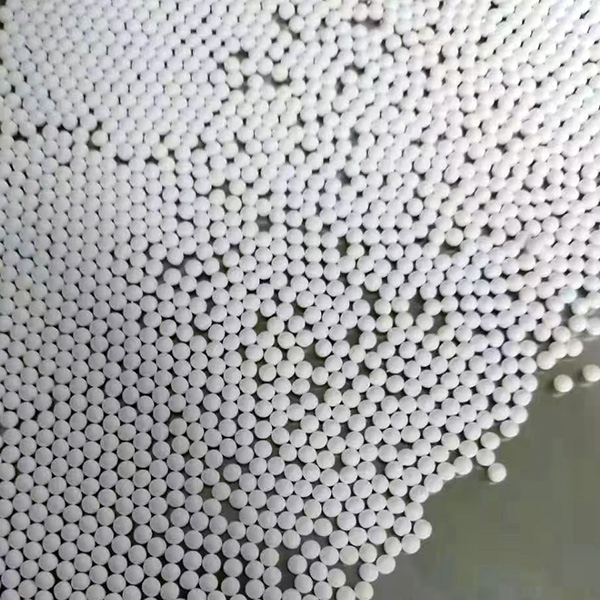

Freeze Dried Pharmaceutical Samples

Such as Pills, API, Injectable formulations, Drugs, Penicillin, Vaccines, Antibodies, Blood, Tissues, Cell etc.

Choose The Right Pharmaceutical Freeze Dryer

Vekuma manufactures pharmaceutical lyophilizers from laboratory research unit to commercial production ones. Shelf area from 0.5m2 to 40m2.