Introduction

The FD-100R industrial large food freeze drying plant can process around 1000kgs raw material per batch.

Fully optimized system, low production cost, short batch duration and stunning freeze dried quality. Vekuma guarantee your profitable production every batch.

Technical Spec.

| Model | FD-100R |

|---|---|

| Shelf Area | 101m2 |

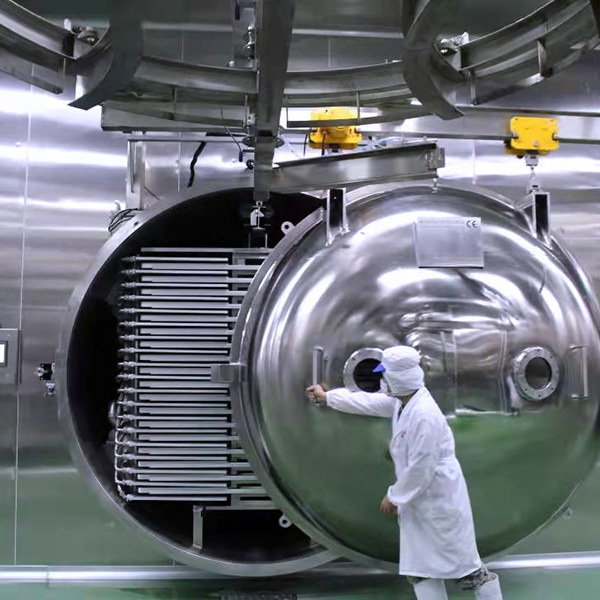

| Shelf Modules | 2 |

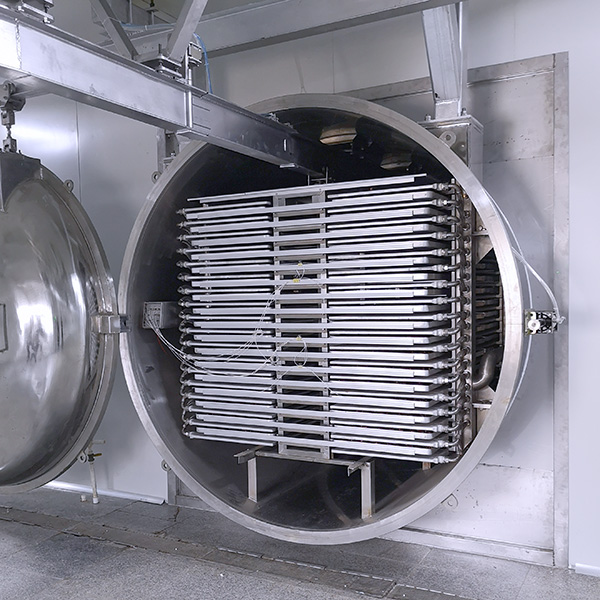

| Shelves No. | 17+1 |

| Shelves Size | 570*5610mm |

| Shelves Temp. | RT~+100C |

| Condenser | 1000Kgs/24Hrs |

| Condenser Temp. | -45C |

| Final Vacuum | <15Pa |

| Power Install | 220Kw |

| Install Area | 12*15m |

Technical Description

- Modular sub-systems, in-site assembly and commissioning.

- S/S304 cylindrical drying chamber, aluminum alloy shelves and trays.

- Slide door with 2pcs large sight glass.

- Heat-plates temperature from RT to +100C.

- External type ice condenser, lowest -45C.

- Condenser hot water defrost

- Material & trays quick loading unloading through trolleys that hanging on overhead monorail.

- Advanced PLC and user-friendly HMI based control system, FD-MEGA software.

- Vacuum system adopt oil sealed pumps + roots pumps combination.

- System final vacuum <0.2mbar, vacuum adjustable.

- Pirani type vacuum sensor.

- Screw compressor based refrigeration system, water cooling for stable performance.

- Turnkey service from plant design, machine produce, shipping, install, commission, to worker training.

- Documents and validation package include in standard offer.