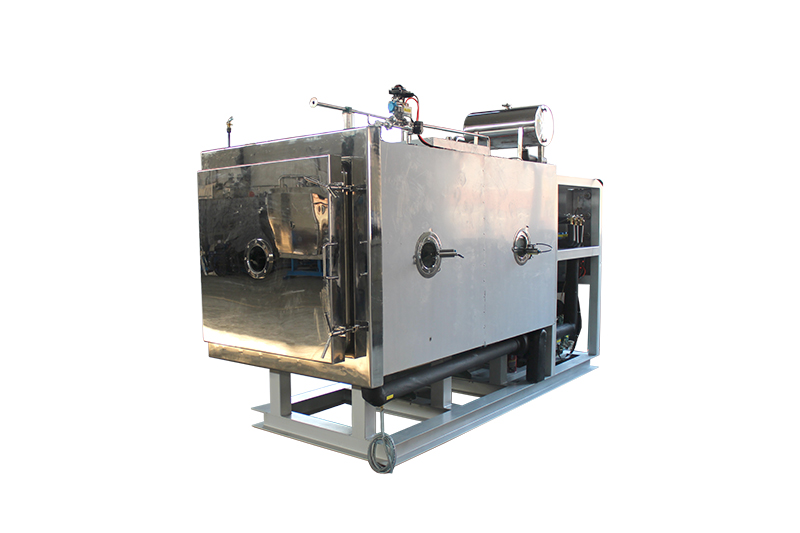

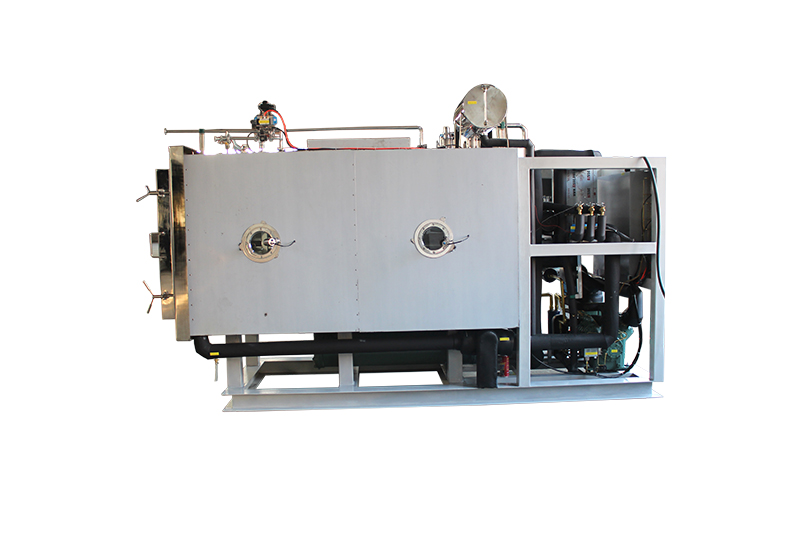

Vikumer FDL series general purpose freeze dryers are designed to dry bulk materials, the range freeze drying equipment fit a wide range of industrial applications include bacterial, yogurt, nutrient, probiotics, reagents.

FDL freeze dryers feature rectangular drying chamber and silicone oil based shelves, achieve the highest space using rate and exceptional temperature uniformity. Guarantees consistent drying results between trays and between batches.

Design Highlights

Rectangular Drying Chamber for Maximum Space Using

The FDL series general purpose freeze dryer features rectangular product chamber which offers the highest space using rate (>90%), and thus, all the heat-plates and product trays have the same size which is easy to handle.

The drying chamber is engineered and produced strictly follow pressure vessel directive, stainless steel made, long lifespan and never distortion. External of the drying chamber wall, up to 150mm thick PUF is covered for insulation

Temperature Controlled Shelves

The shelf system is heat transfer fluid based and is always temperature controlled: heat transfer fluid circulates inside sandwich type heat-plates for product pre-freeze and later heating for sublimation. The shelves are cooled through a brazed plate heat exchanger and are heated by an electric bar. PID control, heating and cooling rate >1C/Min.

An additional heat-plate is installed on top of shelf module to provide extra energy for thermal balance. Temperature sensors have been installed in both the fluid inlet and return pipe, as well as the fluid heating bar point, to control and monitor shelves temperature. Temperature variance between heat-plates and plate points are less than +/-1C.

Exceptional temperature uniformity means the highest freeze dried quality. The proven advantage results the FDL freeze drying equipment are particularly fit freeze dry heat sensitive items such as bacteria, enzymes and probiotics.

Individual Ice Condenser For Better Hygiene

The vapor collect condenser of the FDL lyophilizer is external type, can be installed behind/beneath/lateral of the product chamber, connect to it by a stainless steel pipe, a pneumatic operated butterfly valve can be installed on the pipe for condenser isolate and to perform pressure rise test.

A group of stainless steel coils are installed inside condenser chamber to collect vapors, cooled by refrigerant direct expand and each compressor has independent circuit to guarantee the temperature uniformity. The coils surface area is designed 1:1 compare to shelf area, which result larger vapor collect capacity.

Modular Sub-systems Offer Tons of Benefit

Subsystems such as vacuum pumps, refrigeration compressors, heat transfer fluid pump and heaters are placed below and behind the condenser/chamber. Each sub-system as an individual module and linked together by the PLC. This design has been proved easy to install, maintain and future upgrade. A wide range of accessories and options can be selected to match the particular needs of customers.

Only the best material and strongest components are installed in FDL freeze drying equipment, and are international brands (for key components) and international standards (for pipes, flanges and fittings). So that you can be rest assured that the machine always in ready condition, and can always get prompt services if need.

Industrial Versatile Control System

PLC and user-friendly HMI based control system is applied to FDL commercial freeze dryer, to perform interlock checks, monitoring system working status, execute freeze drying processes and generate alarms. Which includes the following functions.

- Interlock checks and sound-light alarms.

- Alive display main components working status and key parameters.

- Freeze drying recipes management system.

- Real-time freeze drying curve and history drying curve review.

- Drying data-logging and can export to USB memory.

- Automatic and semi-automatic work mode.

- Users and authorizations.

- Sensors calibration.

Superior Quality and Performance Consistency

The FDL general purpose freeze dryers feature sturdy, high quality stainless steel fabricated. Components that installed in sub-systems are from world top brands. Ultimate performance and long life guarantee.

- Shelf Temp. range: -50C ~ +70C

- Shelf lowest: +20C ~ -40C <60min

- Shelf lowest: -50C (+/-2C)

- Shelf heating: -40C ~ +20C <60min

- Shelf highest: +70C (+/-1C)

- Shelf flatness <0.5mm/m

- Shelf roughness Ra<0.4um

- Condenser lowest: -75C

- Condenser cooling: RT ~ -40C <30min

- Condenser coils roughness Ra<0.4um

- Condenser defrosting: <60Min

- Vacuumize: ATM ~ 100Pa <30Min

- Vacuum final: <1Pa

Easy Install and Commissioning

All the machinery that involved with the operation of the FDL freeze dryer is mounted on a steel frame, and a thorough quality and performance test before it is shipped. Ready to operate after connect electric, compressor chilling water and compressed air. Door with decorate panels, easy to integrate into clean room wall. Key components on/off and valves open/close is performed from the remote HMI.

Technical Specifications

| Model | FD-5L | FD-10L | FD-20L | FD-30L | FD-40L | FD-50L |

|---|---|---|---|---|---|---|

| Shelf Area | 5.25m2 | 9.72m2 | 19.8m2 | 29.7m2 | 40.5m2 | 48.6m2 |

| Shelves No. | 7+1 | 9+1 | 11+1 | 11+1 | 15+1 | 18+1 |

| Shelves Size | 750*1000mm | 900*1200mm | 1200*1500mm | 1500*1800mm | 1500*1800mm | 1500*1800mm |

| Shelves Temp. | -50C~+70C | -50C~+70C | -50C~+70C | -50C~+70C | -50C~+70C | -50C~+70C |

| Condenser | 50Kgs/24Hrs | 100Kgs/24Hrs | 200Kgs/24Hrs | 300Kgs/24Hrs | 400Kgs/24Hrs | 500Kgs/24Hrs |

| Condenser Temp. | -75C | -75C | -75C | -75C | -75C | -75C |

| Final Vacuum | <1Pa | <1Pa | <1Pa | <1Pa | <1Pa | <1Pa |

| Power Install | 25Kw | 50Kw | 75Kw | 90Kw | 125Kw | 135Kw |

| Size (W) | 1500 | 1700 | 2000 | 2000 | 2300 | 2300 |

| Size (L) | 4000 | 6000 | 7500 | 9000 | 9500 | 9500 |

| Size (H) | 2200 | 2300 | 2800 | 3200 | 3500 | 3850 |

Technical Details

Tailor-Made and Options

The FDL series freeze dryer can be engineered and manufactured as per user request, Vekuma provide technical support and offer the following options and accessories:

- Conventional and horizontal layout.

- S/S316L material.

- Door position sensor.

- Slide door.

- Coated trays.

- Venting filter.

- HEPA filter.

- Vacuum pump oil mist filter.

- Scroll oil-free vacuum system.

- Capacitive vacuum sensor.

- Chamber and condenser isolation valve.

- Redundant compressor, vacuum pump, fluid pump.

- Eutectic point detector.

- PC control.