The main difference between them is the water remove theory: Vacuum drying based on water boiling point, Freeze drying based on water melting point.

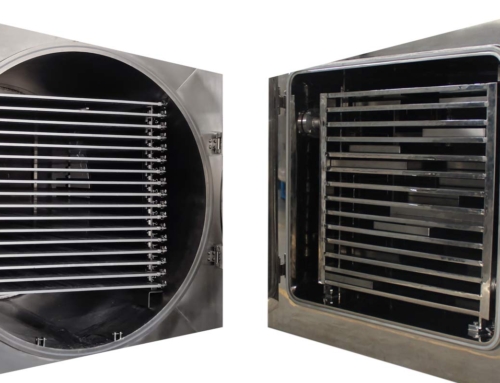

Freeze drying also known as lyophilization. Removes water by freezing raw product, and then reduce its surrounding pressure, to enable solid ice in raw product sublimate directly to vapor. Water remove based on sublimation.

Vacuum drying without freezing stage. By reduce environment pressure, to enable water boiling point reduce, when reach a certain range, the water start boiling and go out of raw product. So, vacuum drying water remove based on water boiling.

Drying Pressure Different

Freeze drying process, vacuum range typically <133pa. While vacuum drying is higher, about 1000~5000pa.

This because freeze drying removes solid phase water: Solid to vapor, which called sublimation. Vacuum drying removes liquid phase water: Liquid to vapor, called evaporating. The sublimation or evaporating request different pressure.

Drying Temperature Different

Freeze drying process, most time is below zero degree, only in secondary drying stage, a coupe of hours, will higher zero, but below 30C.

Vacuum drying, the whole process is between 40C and 80C.

Results Are Different

| Freeze Drying | Vacuum Drying | |

|---|---|---|

| Cost | High | Middle |

| Dried Quality | High | OK |

| Production | By Batch | Continuous |

| Heat Sensitive Product | Yes | No |

| Dried Product Structure | No Change | Slightly Change |

| Application | All Industries | Mainly Food and Beverage |