The Freeze Drying Technology

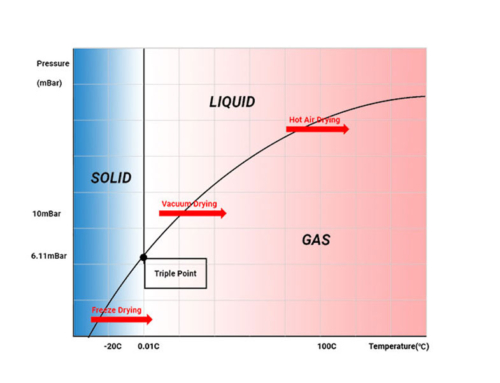

Vacuum freeze drying (also called lyophilization in bio-pharma industry) is one of the common used dehydration methods. Its key advantage is gently dry products without ruin their properties (current, freeze drying is the only method to deliver stable, biologically active products with a long shelf life). Thus, freeze drying can apply to nearly every industry, unlimited applications.

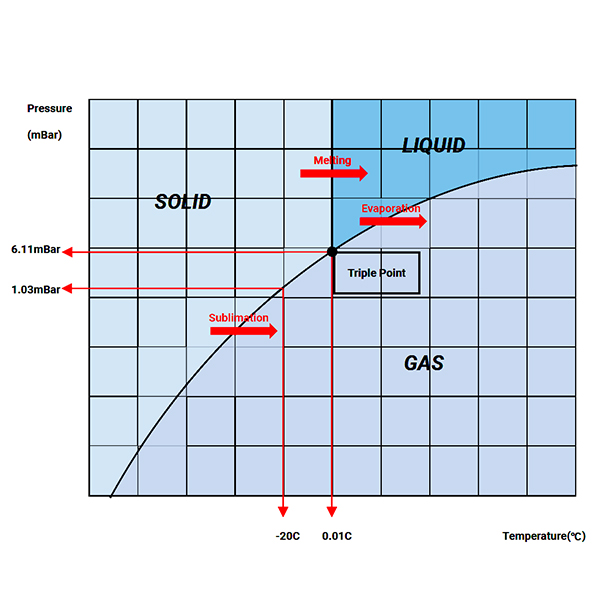

Freeze drying removes water by use a technology which called sublimation that is, under water triple point (6.11mbar, 0.01C), no liquid water exist, the phase transfer of water is between solid and gas.

Since sublimation technology, water changes from solid to gas. So, freeze drying process must starts from raw product freezing, and then apply vacuum, to create sublimation condition.

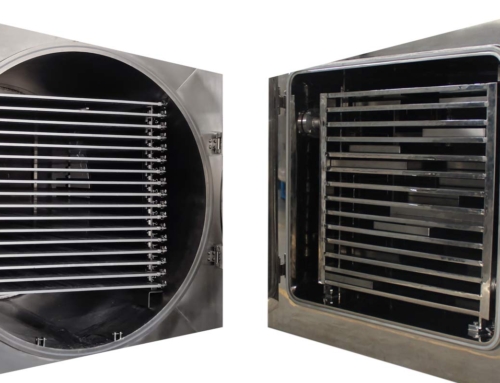

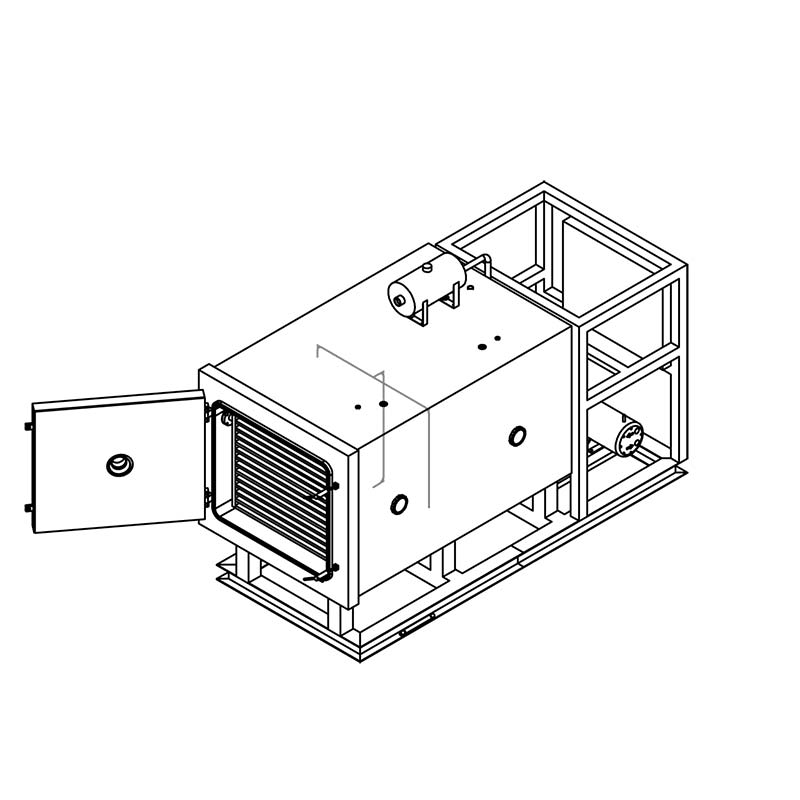

The Freeze Dryer Machine

Freeze drying equipment is designed base on freeze drying theory and is built to process freeze drying. By intentionally change drying chamber temperature and pressure to create sublimation conditions, to enable solid water sublimate to vapors and come out from raw products.

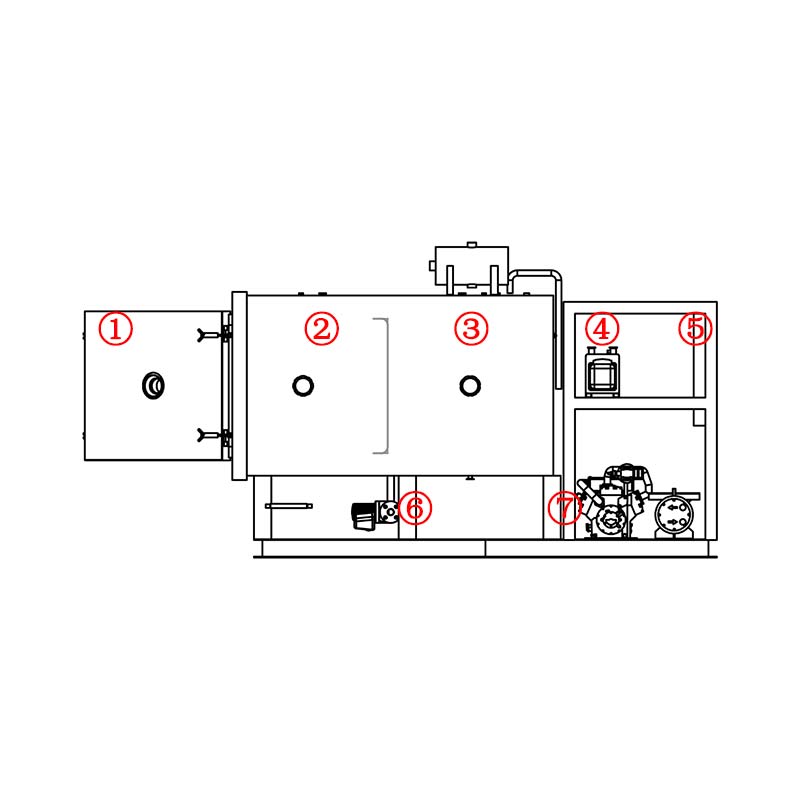

Thus, a freeze dryer machine includes several necessary key parts: A drying chamber to place products, an ice condenser to store collected vapors, refrigeration system to cool ice condenser, vacuum system to maintain chamber pressure, control system use to control freeze dryer.

How Water Is Removed

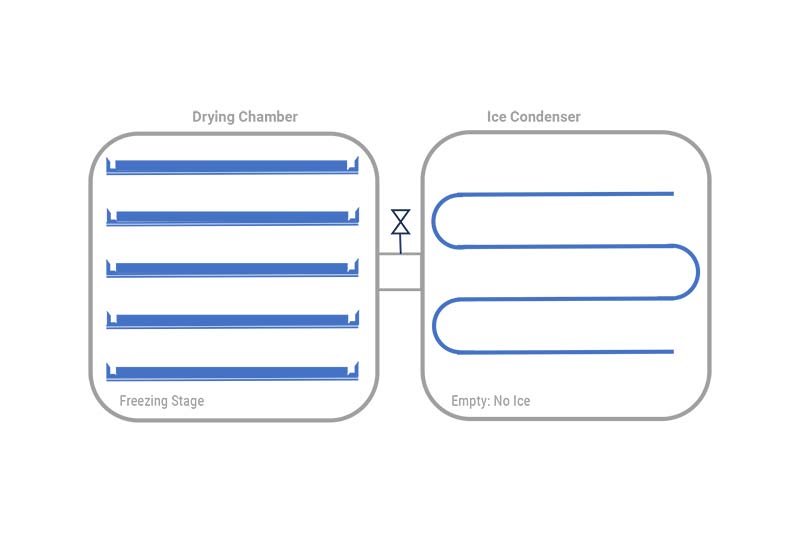

Firstly, frozen products are placed in drying chamber, ice condenser starts cooling.

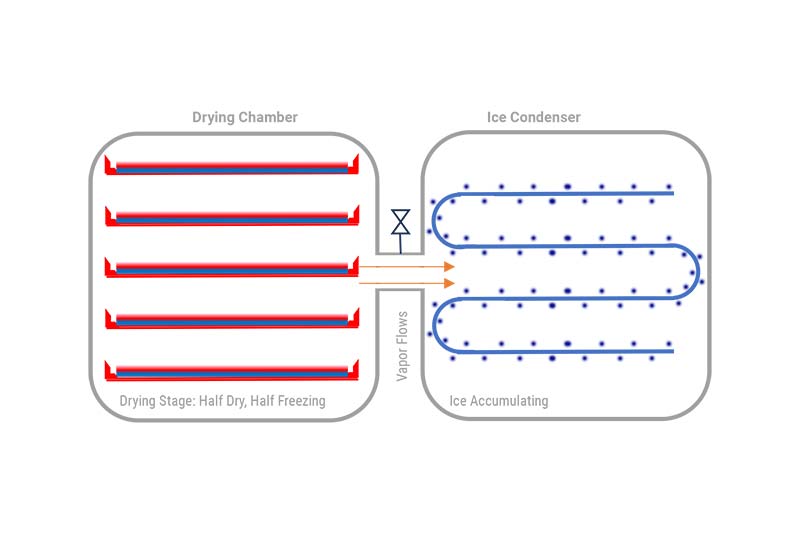

Secondary, vacuum pumps start work and pull chamber pressure to negative; solid water (ice) in raw products absorb environment heat and sublimate to vapors; low-temperature condenser cause lower surrounding pressure than drying chamber, so that vapors flow into ice condenser by pressure difference; vapors hit ultra-low temperature condenser and turn to solid phase again, store by ice form.

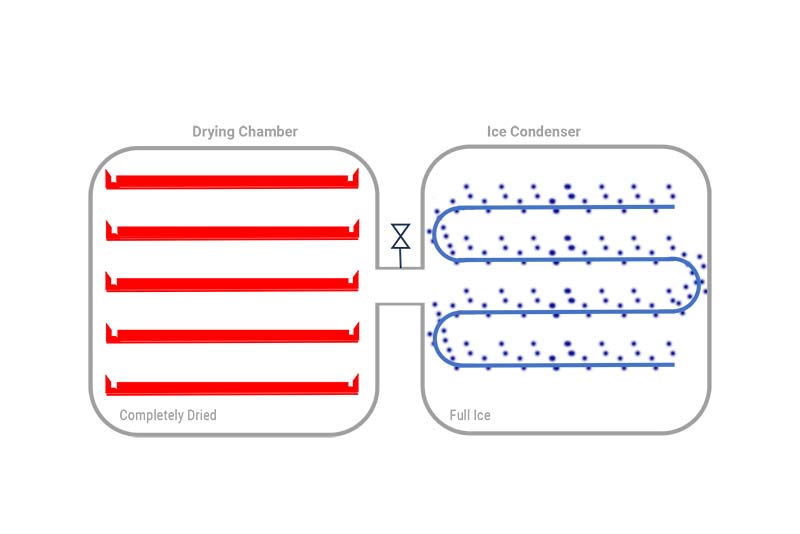

Third, products completely dried, water inside products all moved to ice condenser.

Following pictures show water location changes (inside raw products VS ice condenser), (before, during and after) freeze drying.

So, the freeze drying system doesn’t remove water, it just changes the water location: From the product to the ice condenser (the water is still inside the freeze dryer machine). The theory is by several times water phase change: Liquid to Solid (raw product pre-freezing), Solid to Vapor (Sublimation), Vapor to Solid (Vapor condensing in ice condenser).