Introduction

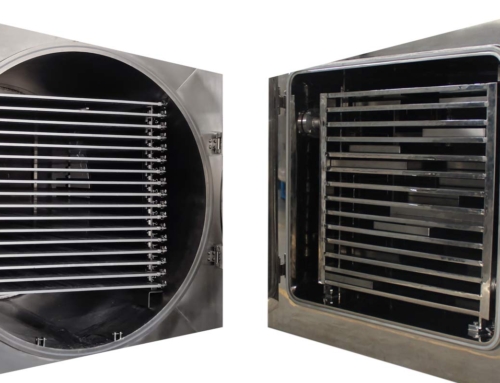

The shelf module is installed inside freeze drying chamber, typically, it contains several heat-plates. Main functions include: Hold material trays, Pre-freeze materials and Supply heat energy to speed up the sublimation.

Based on applications and industries, the shelf module designing is different. In this article, we will have a completely introduction of the shelves in freeze drying system: Material, Temperature, Structure and heating methods.

Material

Mainly, the shelves are fabricated from stainless steel or aluminum alloy.

- S/S304 suit common industries like biologicals, nutritions, probiotics etc.

- S/S316L is ideal for industries that request higher hygiene level like pharmaceutical, or raw materials contains corrosive properties like chemicals.

- Aluminum alloy shelves mainly adapt to food industry.

Structure

There are mainly 2 structures of shelf module:

- Fixed shelves for bulk (Products are loaded and dried in material trays).

- Flexible shelves for stoppering (Products are loaded and dried in vials, later capping under vacuum environment).

Heat Transfer

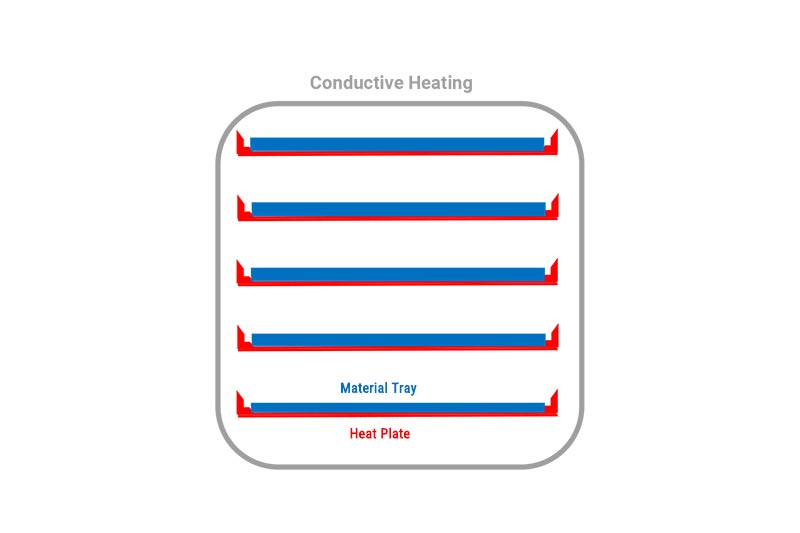

There are mainly 2 heat transfer methods that from shelves to materials:

- Conductive heating (Material trays directly put on heat-plates).

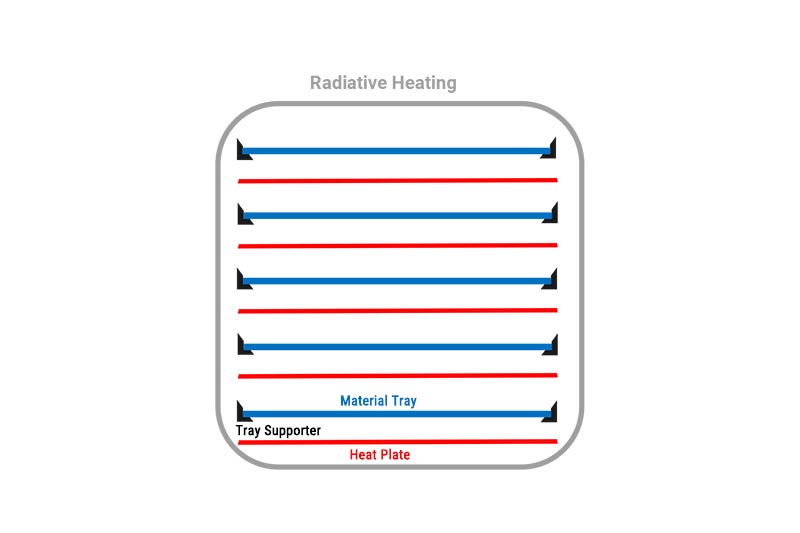

- Radiative heating (Material trays suspend between 2 shelves).

Chilling and Heating

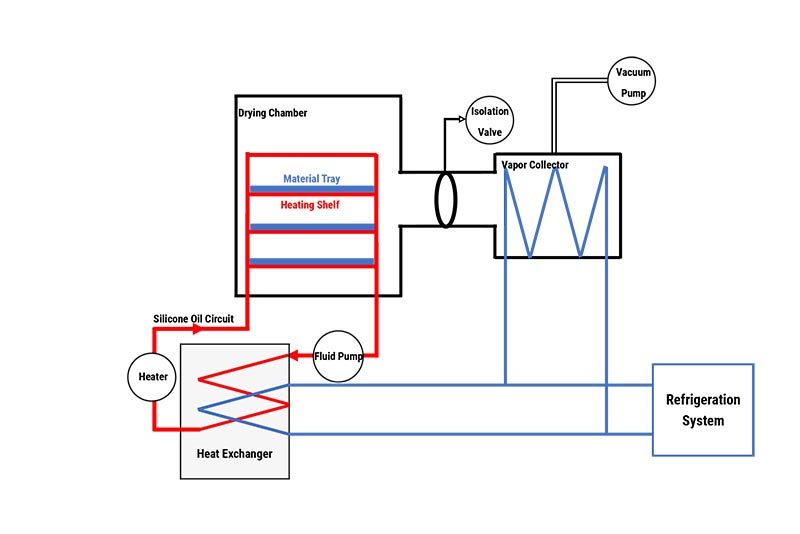

The shelves cooling and heating is by heat transfer fluid circulates inside the heat-plates. The heat-plates are sandwich structure, hollow internal have welded channels, to enable fluids flow through. A centrifugal pump is use to pump the heat transfer fluid, to circulate between shelves, heat exchanger and pipes.

The heat transfer fluid cooling is indirectly through an intermediate plate heat exchanger which connect with refrigeration cycle. The fluid heating is directly by an electric heating bar.

Temperature Design

The shelves lowest and highest temperature design is based on raw product features. The lowest shelf temperature is based on freezing points of raw material (at least 15C lower), the highest shelf temperature mostly between +60C to +100C.

- For common items,like food, probiotics, plant exacts and enzymes, the shelves lowest -25C to -35C is enough.

- For biological and pharmaceutical products, the shelves lowest -55C to -65C is ideal.