Introduction

The ice condenser plays an important role in a freeze dry system, directly influence the success of freeze drying. Main function of this part is collect vapors that come out from the raw material.

In this article, we will have a completely introduction of the vapors collect condenser: Types, Working theory, Temperature, Defrosting methods and Key points need pay attention to when select the right freeze drying machine.

Types

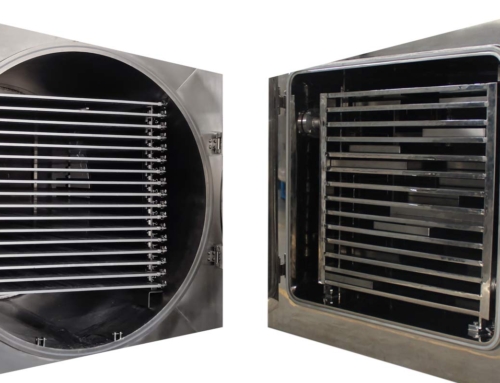

Generally, there are 2 types of ice condenser: External and Internal.

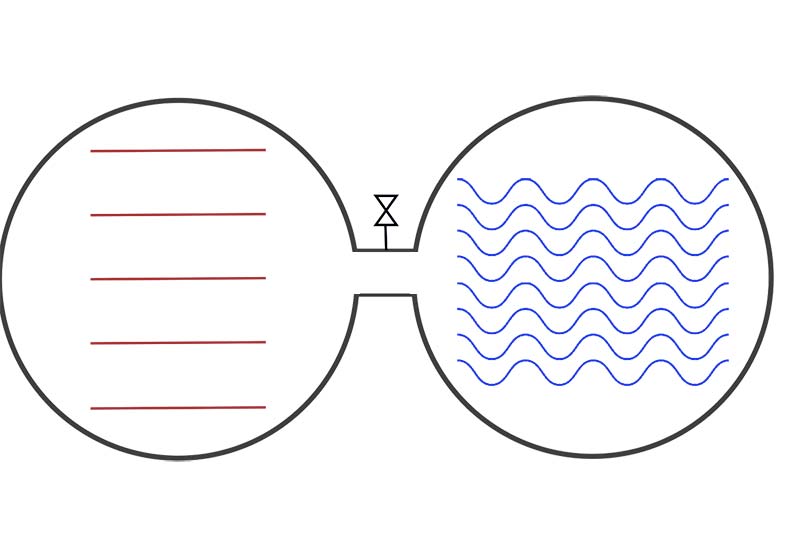

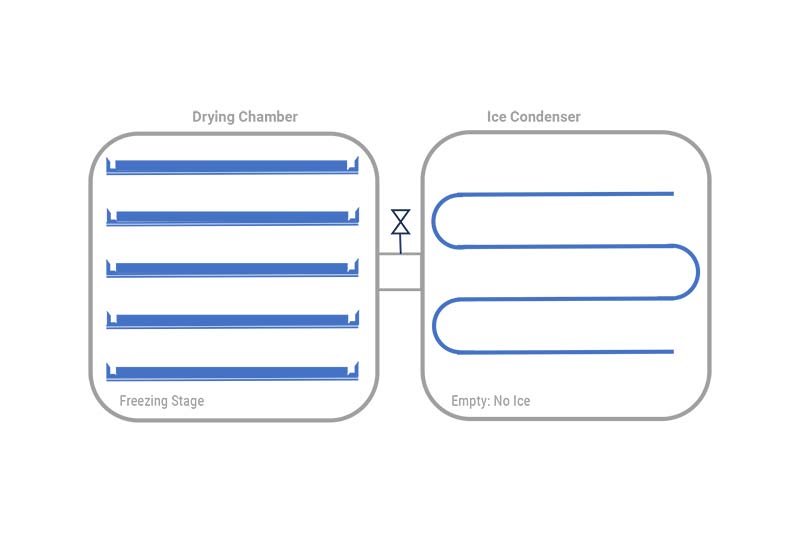

Freeze dryer with external type ice condenser, typically called 2 chamber system (drying chamber and ice condenser are 2 individual containers, connect with each other by a S/S pipe), the ice condenser can be formed rectangular or cylindrical, installs beneath or behind drying chamber.

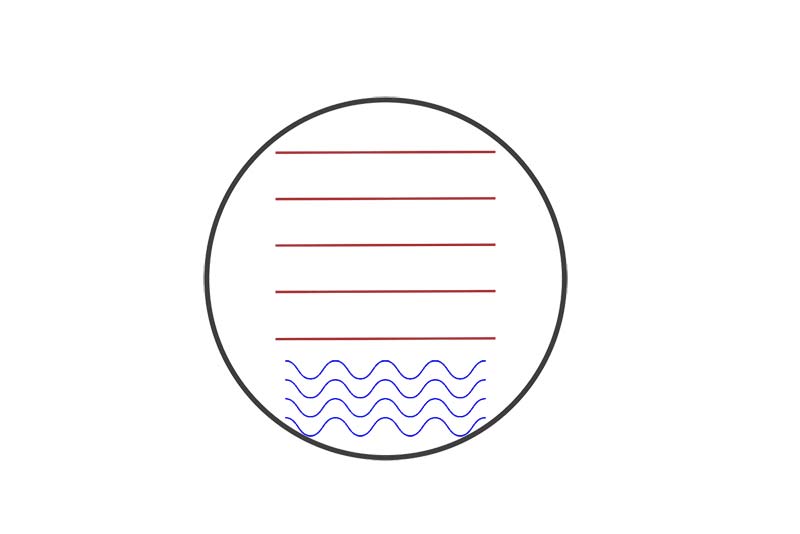

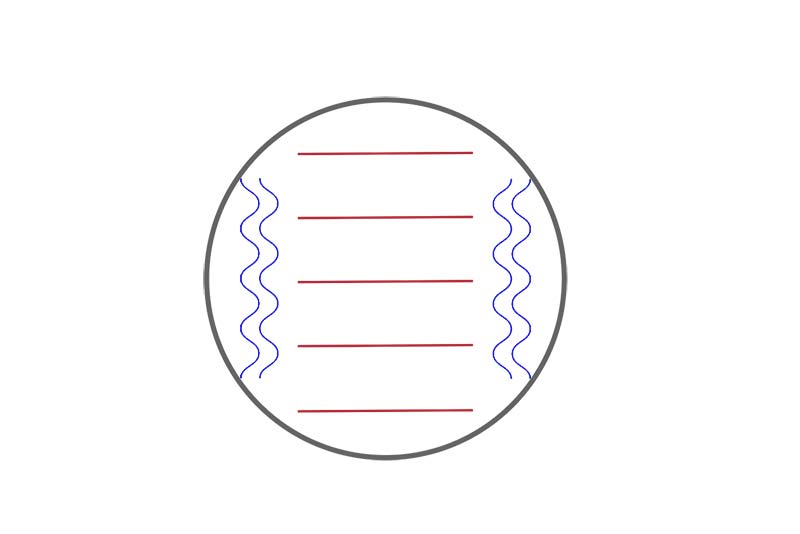

Freeze dryer with internal type ice condenser, typically called single chamber system (drying chamber and ice condenser share 1 container), condensing coils can be placed beneath or besides shelf module.

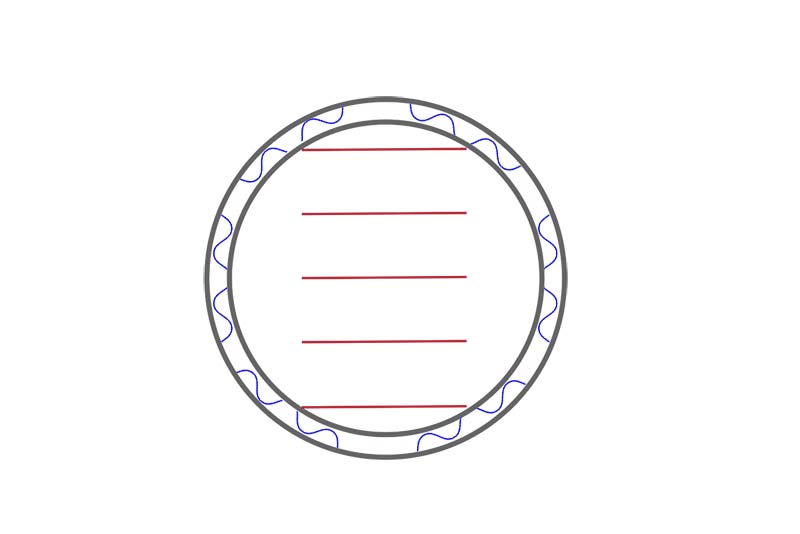

There is one more type ice condenser: The integrated ice condenser, which mainly use in home freeze dryers, vapors collect coils are arranged on external of the drying chamber wall (jacketed wall structure), the drying chamber (internal) wall roles as the vapor collector.

Working

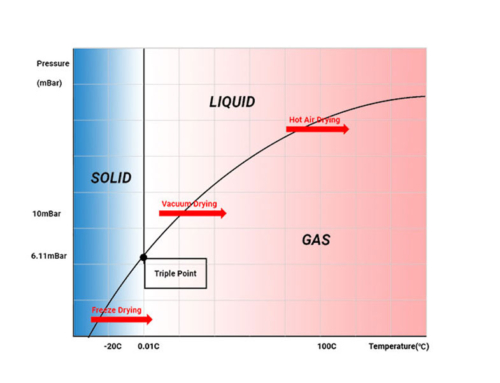

The freeze drying system removes water from raw products and store them in the ice condenser. The water removing process is a “Solid, Vapor, Solid” process:

- Firstly, products are frozen before freeze drying starts, the water is solid phase.

- Secondary, sublimation starts, the solid water inside products sublimate to vapor phase.

- Third, vapors hit ultra-low temperature condenser and turn to solid phase again.

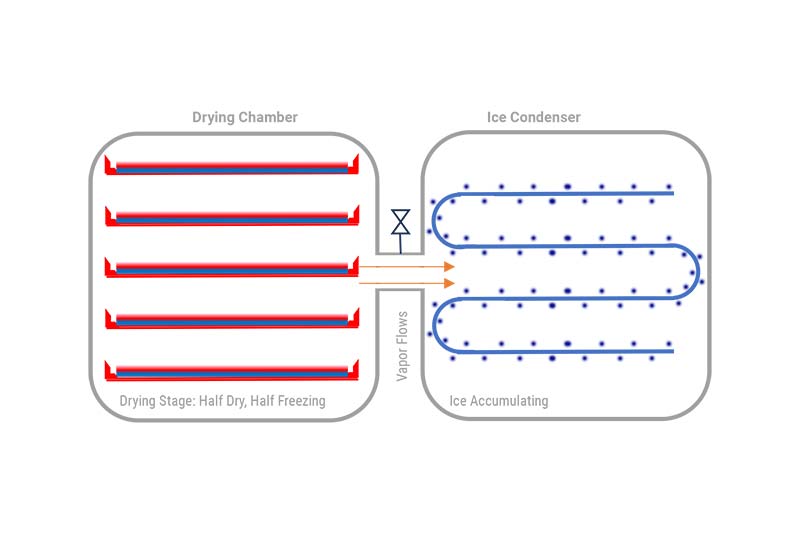

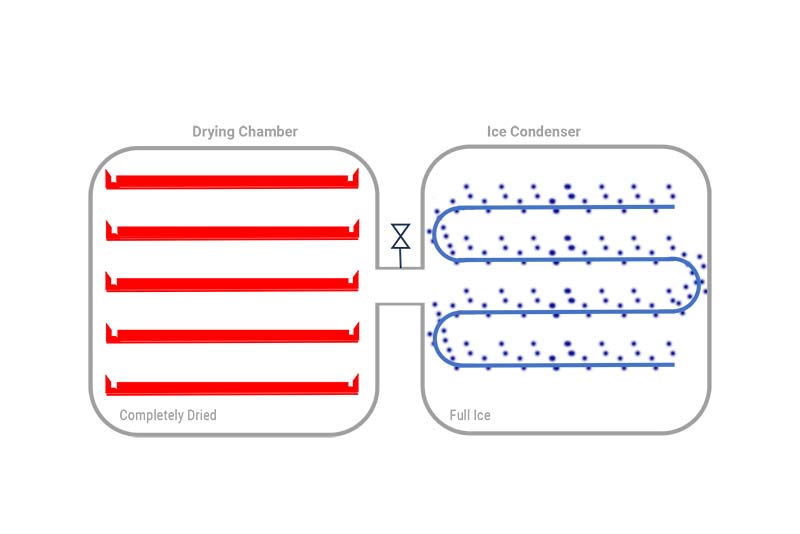

Following pictures show the water location (inside raw products and ice condenser), before, during and after freeze drying.

The ice condenser (condenser coils) directs connect to refrigeration system, and is chilled by refrigeration direct expand, it is working principle is quite simple.

Temperature

Since the ice condenser is cooled by refrigerant direct expand, so, as per refrigeration system debug, the ice condenser has a wide temperature range, typically from -35C to -110C.

Selection of the ice condenser temperature is based on raw product features. Typically, ice condenser temperature should be 15~20C lower than raw material’s freezing points. Only this, vapors that come from the raw material can effective icing in condenser.

- Medium temperature (-35C around) ice condenser mainly use in food freeze drying equipment.

- Low temperature (-55C around) ice condenser mainly applied in freeze dryers that use to dry yogurt, bacterias, enzymes and probiotics.

- Ultra-low temperature (-85C around) ice condenser mainly use in bio and pharmaceutical freeze dryers.

- Ultimate temperature (-110C around) ice condenser mainly use in chemical freeze dryers that when raw material contains solvents.

Defrosting

There are mainly 3 defrosting methods: Hot gas, Electric bar heating and Water.

- Hot gas defrosting thoery is reverse the refrigerant flows, to enable the high-pressure refrigerant vapors warm the condensing coils, to melt accumulated ice.

- Electric bar heating for defrost is simple structure, electric bars typically install together with condenser coils, while the bar is heating, temperature raise and ice is melted.

- Disadvange of hot gas and electric bar heating for defrost, they take longer time and may not complete, because the ice pieces may drop to condenser bottom, where cannot be heated.

- Hot water defrost is high efficiency, by send hot water into ice condenser, ice is melt quickly and completely.