Brief Introduction

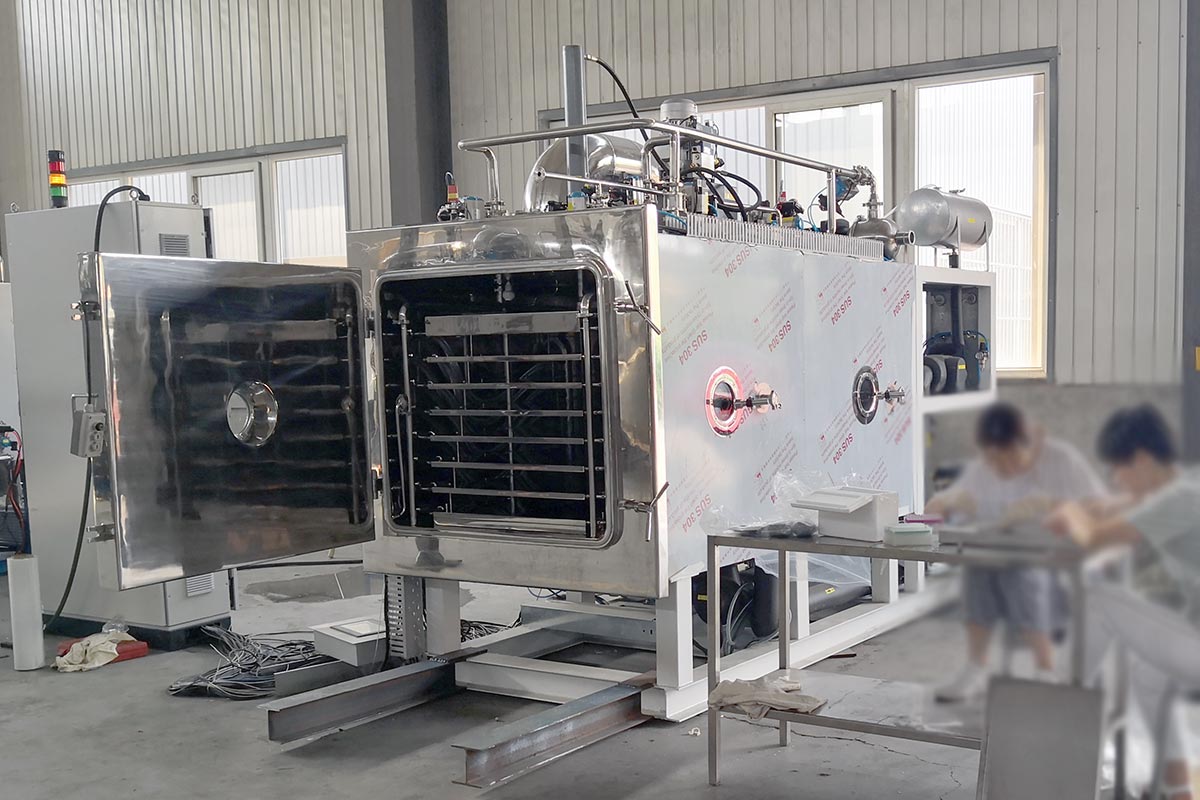

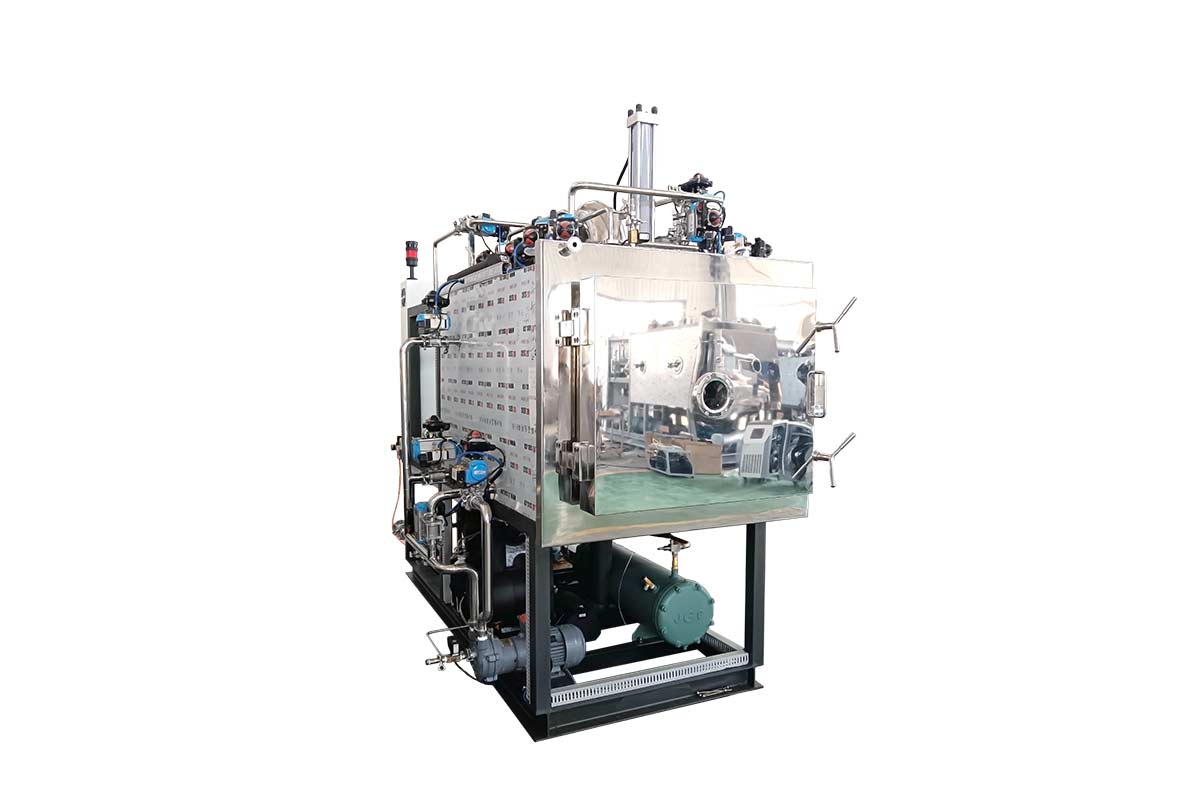

Vikumer’s pharmaceutical freeze dryers are GMP lyophilizers that can be addressed to all pharmaceutical and biology industries. Freeze drying materials in trays, vials or glass containers. Shelf area up to 50m2 and condenser capacity up to 800kgs.

Technical Details

The FDLS pharmaceutical freeze dryers are specifically designed to meet GMP requirements for industrial applications that include pharmaceutical and biological manufacturing such as vaccines, antibiotics, serum, penicillin, hormones and reagents. The range lyophilizers can be equipped with CIP and SIP system to satisfy commercial aseptic production needs.

The FDLS series pharma freeze dryer and lyophilizer can be configured to maximize production capacity and optimize floor space. They can be designed integrated structure or 2 floor installation.

Standard Features:

- 2 chambers system meet maximum hygiene requirement.

- Rectangular drying chamber and ice condenser, high space using rate and high temperature uniformity.

- Isolation valve installs between chamber and condenser for pressure rise test, leak rate test and capable of automatic close once a power outage occurs.

- Delicate designed fluid circulates system guarantees uniform temperature of shelves and across the drying chamber.

- Adopt “internal welding” technology to ensure the flatness and air-tightness of shelves.

- Shelf slope temperature control.

- Hydraulic stoppering system with pressure monitoring and is adjustable to reduce vials breaking rate.

- Ice condenser coils surface area 1:1 comparing to the shelf.

- Automatic CIP/SIP process and semi-automatic CIP/SIP as per parameters setting.

- Drying chamber, ice condenser and all pipelines are under pressure vessel guidelines.

- All valves that use to isolate air and water are pneumatic operated, rapidly open/close and are capable of auto close once a power outage occurs.

- World top class components and international standard valves, pipes, flanges and sensors.

- Machine structure, functions and components brand can be customized.

- Quality and performance test before shipment.

- FDLS freeze dryers are easy to integrate with other equipment in production line.

Superior Quality and Performance Consistency

Vekuma’s pharmaceutical freeze dryers feature sturdy, stainless steel fabricated chamber and ice condenser, internal accessories like shelves, pipes and fittings etc. are made by S/S316L. Components that installed in sub-systems are from world top brands. Ultimate performance and long life guarantee.

- Chamber inner wall roughness Ra<0.6um

- Shelves flatness <0.5mm/m

- Shelves roughness Ra<0.4um

- Shelf cooling: +20C ~ -40C <60min

- Shelf lowest: -55C (+/-2C)

- Shelf heating: -40C ~ +20C <60min

- Heating final: +70C (+/-1C)

- Condenser inner wall roughness Ra<0.6um

- Condenser coils roughness Ra<0.4um

- Condenser cooling: RT ~ -40C <30min

- Condenser final: -85C

- Defrosting: <60Min

- Vacuum final: <1Pa

Industrial Versatile Control System

Based on high advanced PLC and user-friendly touch screen HMI, to control all the machine functions, performs all interlock checks, and generate processes and device alarms. Capable of automatic execute the freeze drying steps you are programmed, monitoring system running status, protect your freeze dry system and raw product all the time.

The control system has been pre-programmed a bunch of protection logic such as: System auto shut down if chamber pressure not reduce; Vacuum pump will not active if condenser temperature not reach set to avoid vapor flows into vacuum pump and damage it; Once a failure appears, sound-light alarm and touch screen HMI shows possible failure reason, meanwhile, all air and water isolate valves auto close to maintain chamber pressure and protect your products.

The delicate designed LYO-MEGA V2.0 guarantees your drying data and drying steps that stored in HMI will not lose once a power outage, and the drying process will continue after power restoration. As well as, it supports operator modify the current-running freeze drying steps (while machine is in operation), system will auto execute the latest modified drying recipe.

The LYO-MEGA V2.0 interface functions:

- Graphic display main components working status and key parameters.

- System and key parts functional test.

- Automatic and semi-automatic work mode.

- Freeze drying recipes management.

- Automatic and semi-automatic CIP/SIP control.

- Real-time freeze drying curve.

- Historical curve review.

- Drying data-logging and can be exported via USB.

- Users, password and authorizations.

- Sensors calibration.

- Alarms.

Modularly Engineered Enable Flexible Configuration

The FDLS freeze drying equipment are designed and manufactured modularly, which can be configured flexibly as per needs. All its sub-systems are standardized, international level and components are finished meet the strictest international standards. This solution has been proved maximum reliability and cost effective. Options include:

- CIP clean in place.

- SIP sterilize in place.

- Auto door lock (pneumatically).

- Door position sensor.

- Slot door.

- Variable shelf spacing.

- Butterfly or mushroom valve for chamber&condenser isolate.

- Venting filter.

- HEPA filter.

- Vacuum pump oil mist filter.

- Proportional air valve.

- Capacitive vacuum gauge.

- Redundant compressor, vacuum pump, fluid pump.

- Eutectic point detector.

- PC control.

- SCADA package.

- FAT and report file.

- System Validation documentation IQ, OQ.

- SAT and IQ, OQ execution.

- Install, commissioning and worker training.