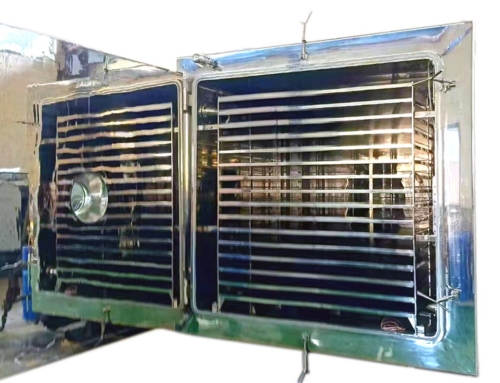

Multi-Purpose Industrial Freeze Dryer

Vekuma’s FD-30L freeze dryer is an industrial large capacity vacuum freeze drying equipment that designed for a range of commercial applications such as probiotics, bacterial, dairy, chemicals and bulk materials. Raw products can be solid, fluid, paste, granular and irregular shape, loaded and freeze dried in material trays.

The FDL multi-purpose freeze dryer features rectangular drying chamber which has the highest space using rate and exceptional temperature uniformity. Which result they are particularly fit freeze dry heat sensitive items and guarantee the consistent freeze dried results.

The FD-30L freeze dryer has 29.7m2 shelf area that enable load products, couple with a high performance ice condenser which can collect 300kgs vapors in 2hrs period, condenser lowest -85C. The control system is PLC and touch screen HMI based, capable of auto and semi-auto freeze dry and graphically display main components working status and key parameters, as well as the data logging functionality.

Technical Specifications

| Model | FD-30L |

|---|---|

| Shelf Area | 29.7m2 |

| Useable Shelves | 11 |

| Shelves Size | 1500*1800mm |

| Shelves Temp. | -50C~+70C |

| Condenser | 300Kgs/24Hrs, 600Kgs Max. |

| Condenser Temp. | -75C |

| Final Vacuum | <5Pa |

| Power Install | 85Kw |

| Size | W/2000*L/9000*H/3200mm |

Technical Description

- All-in-one design, pre-assembled and completely tested before shipment.

- 2-chamber system, high hygiene level.

- Rectangular drying chamber and ice condenser, high space using rate.

- Entirely S/S304 fabricated, long lifespan fit commercial heavy use.

- Fixed shelf module fits drying bulk products.

- All heat-plates are sandwich type, heat transfer fluid circualtes inside for products heating and chilling.

- Silicone oil based shelf heating and chiling system, high temperature uniformity guarantee.

- 2-stage oil sealed vacuum pump quick pull chamber pressure down to set.

- Vacuum auto regulate to set point/range.

- 2-stage reciprocating compressor based refrigeration system, water cooling method for stable performance.

- Refrigeration system cool shelves in pre-freeze stage and 1st drying stage, also cools condenser during freeze dry.

- Advanced PLC and user-friendly HMI based control system, FD-MEGA V2.0 interface, FDA 21CFR PART 11 compliant.

- Documents and validation package supply.

- Permanent technical support.

- After sale service parts supply.

- Tailor-made.

System Performance

- Shelf cooling: +20C ~ -40C <60min

- Shelves lowest: -50C

- Shelf heating: -40C ~ +20C <60min

- Shelves highest: +70C

- Shelf temperature uniformity: <+/-1C

- Condenser cooling: RT ~ -40C <30min

- Condenser final: -75C

- Defrosting: <60Min (+65C Water)

- Vacuumize to 100Pa: <30Min

- Vacuum final: <1Pa

- Chamber leak rate <5Pa L/Sec

- Chamber inner wall roughness Ra<0.6um.

- Shelves flatness <0.5mm/m.

- Shelves roughness Ra<0.4um.

- Condenser inner wall roughness Ra<0.6um.

- Condenser coils roughness Ra<0.4um.