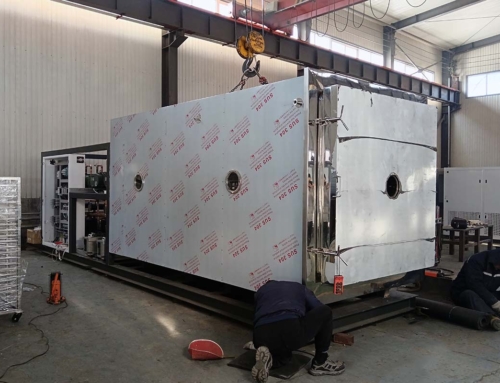

40.5m2 Production Freeze Dryer

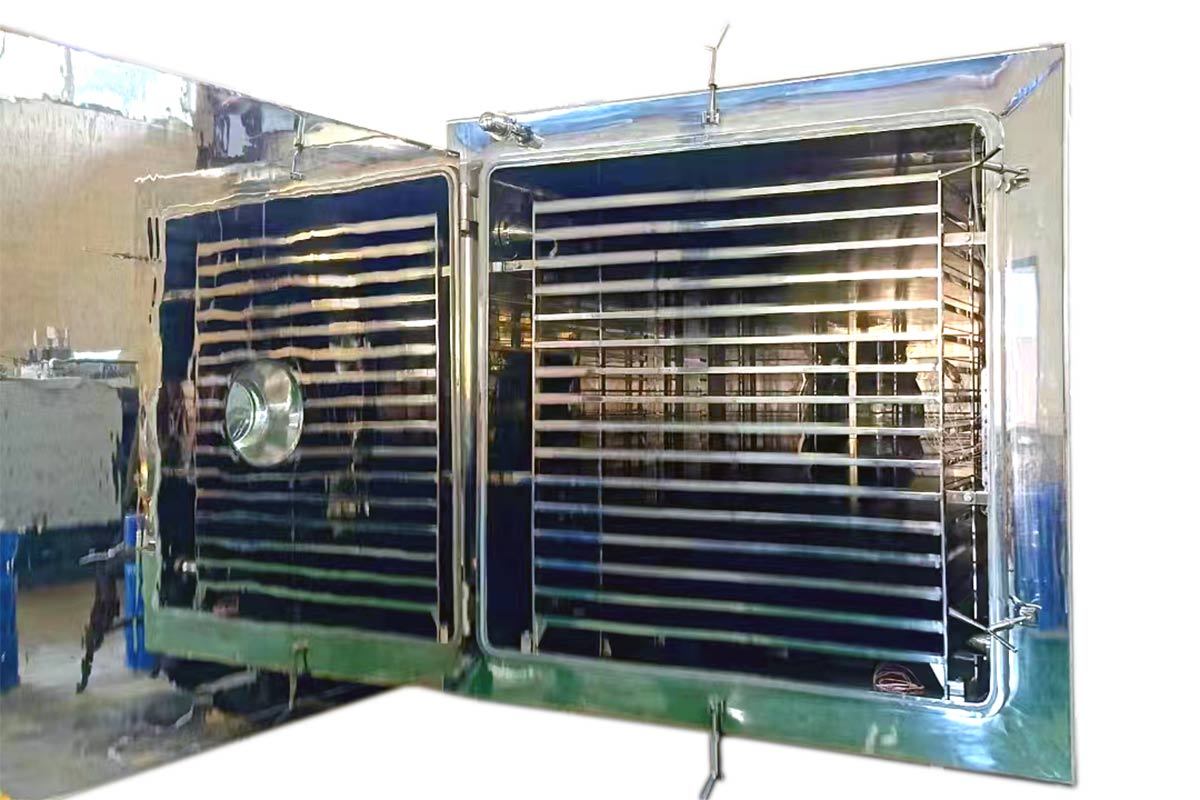

The FD-40L freeze dryer is an industrial large production freeze drying unit, designed to process heat sensitive materials like probiotics, nutritional products, bacteria, enzymes and a range of biological items. The freeze dry machine has 40.5m2 shelf area and a 400kgs/24hrs ice condenser. It features rectangular shape drying chamber which means highest space using rate and superior temperature uniformity acorss the chamber.

Technical Specifications

| Model | FD-40L |

|---|---|

| Shelf Area | 40.5m2 |

| No. of Shelves | 15+1 |

| Shelves Size | 1510*1810mm |

| Shelves Temp. | -50C~+70C |

| Condenser | 400Kgs/24Hrs, 800Kgs Max |

| Condenser Temp. | -75C |

| Final Vacuum | <5Pa |

| Power Install | 125Kw |

| Size | W/2300*L/9500*H/3500mm |

Technical Description

- Entirely S/S 304 fabricated.

- Integrated structure or split structure.

- Industry versatile FD-MEGA control system, PLC and HMI based.

- Rectangular drying chamber with PUF insulation.

- 2 chambers system, ice condenser installed behind drying chamber.

- Sandwich type heat-plates, heating and chilling function.

- Shelves temperature auto balance system, guarantees all heat-plates temp. variance <+/-1C.

- Ice condenser lowest -75C.

- Reciprocating compressor or screw compressor system, water cooling method.

- Each compressor has individual circuit to ice condenser, evenly condenser temperature.

- 2-stage oil-sealed vacuum pump and roots pump system.

- Drying chamber pressure final <0.05mBar.

- All air and water isolate valves are pneumatic operated. Electric interrupt, valves automatic close to protect raw material.

- IQ, OPQ, document package include.

System Performance

- Chamber inner wall roughness Ra<0.6um

- Chamber internal corners are rounded.

- Shelves flatness <0.5mm/m

- Shelves roughness Ra<0.4um

- Shelf cooling: +20C ~ -40C <60min

- Cooling final: -55C (+/-2C)

- Shelf heating: -40C ~ +20C <60min

- Heating final: +70C (+/-1C)

- Condenser inner wall roughness Ra<0.6um

- Condenser coils roughness Ra<0.4um

- Condenser cooling: RT ~ -40C <30min

- Condenser final: -85C

- Defrosting: <60Min

- Vacuum final: <5Pa